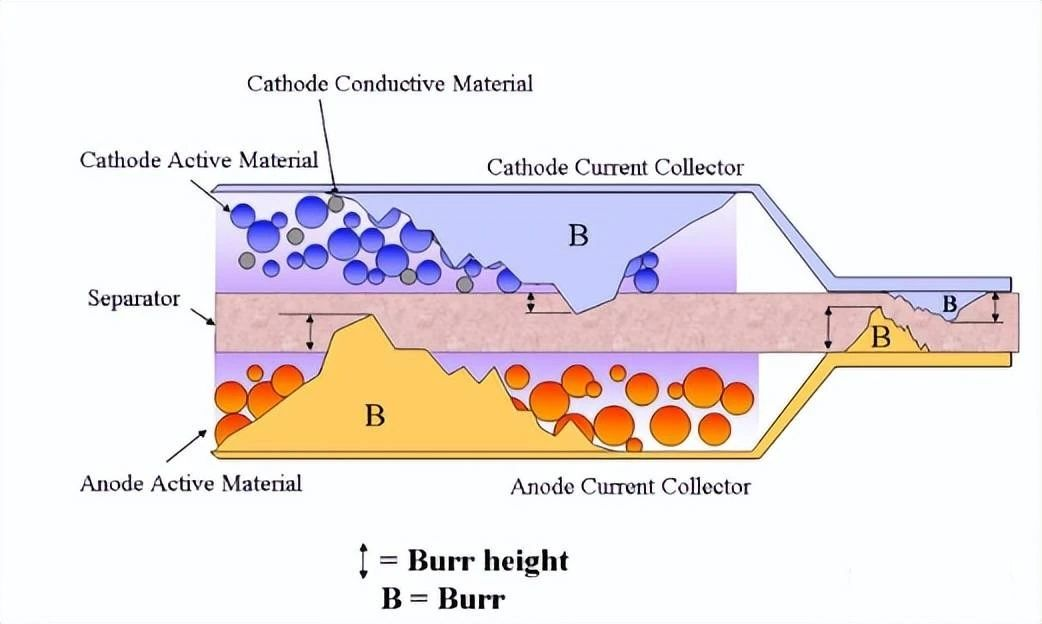

According to the IEEE1725 Standard for Safety Performance Review and Testing of Electric Cells, burrs are metal protrusions that extend from the foil (i.e., uncoated areas) to the outside of the electrode, using the foil as the reference line; Or in areas with coatings, metal protrusions extending upwards or downwards from the coating to the outside of the electrode; The measurement of burr size is to measure the height of the burr in the vertical direction.

Excessive burrs can easily puncture the diaphragm, leading to short circuit caused by positive and negative pole contact. If a short circuit occurs when the battery is in a fully charged state, a large amount of heat will be immediately released internally, causing an explosion, seriously endangering the safety of consumers' lives and property.

In order to produce batteries of different sizes, the electrode plates after coating and rolling also need to undergo processes such as slitting and punching. Taking the cutting process as an example, the physical and mechanical properties of the electrode itself, the overlap of paired cutting tools, and the wear status of the cutting edge can all affect the generation and size of burrs.

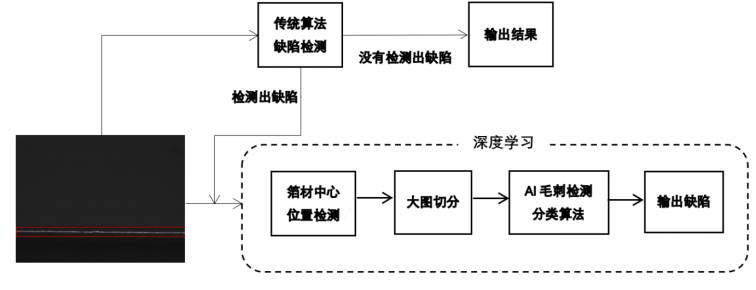

From the perspective of testing requirements, in order to comprehensively control product quality, it is not only necessary to detect whether there are burrs, but also to make different judgments based on the size of the burrs. From the perspective of detection methods, electrode burrs are often detected offline using a visual microscope, but even with a large depth of field microscope, there are still problems with insufficient depth of field and magnification. At the same time, in order to complete the measurement function, multiple systems need to operate simultaneously, which is cumbersome and increases costs.

Our independently developed optical system achieves adaptive focusing, improves system depth of field, achieves high-resolution, large field of view, and high-speed imaging with large depth of field, achieves stable and clear imaging at a speed of 150m/min, and completes full inspection of electrode edge burrs with a detection resolution of 2 μ M.

For battery companies, detecting and handling defects is only the first step. Full production line management and full process management are the development directions for further improving product quality and ensuring product safety.

The online full inspection system for burrs also has functions such as labeling linkage, alarm prevention, etc. It can also be linked with the enterprise's own MES, interact with data centers and terminal storage, meet the requirements for the retention period of enterprise defect information, and achieve data traceability and traceability.